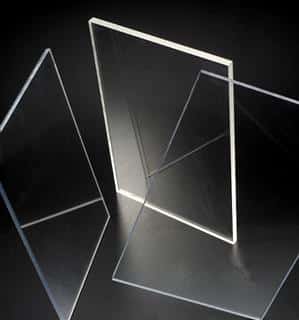

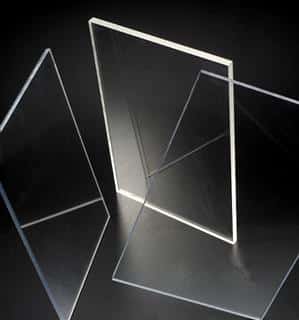

Polycarbonate Sheet

Polycarbonate versus Acrylic

Polycarbonate sheeting is often confused with Perspex, which is a brand name for a type of acrylic. While acrylic has some common features with polycarbonate sheeting, the two materials are not the same.

Polycarbonate is significantly stronger than acrylic, making it more suitable for applications that require high impact resistance. It also has a higher optical clarity than polycarbonate, making it suitable for installations such as Covid and security screens in shops, banks and public buildings.

When it comes to strength, durability and weather resistance, polycarbonate sheeting will usually be the best choice.

Showing all 6 results

-

2mm Polycarbonate Sheet

£2.11 – £54.72 ex VAT Select options This product has multiple variants. The options may be chosen on the product page -

3mm Polycarbonate Sheet

£2.17 – £82.08 ex VAT Select options This product has multiple variants. The options may be chosen on the product page -

Other Thicknesses Available – Click For A Quote!

£0.00 ex VAT Select options This product has multiple variants. The options may be chosen on the product page -

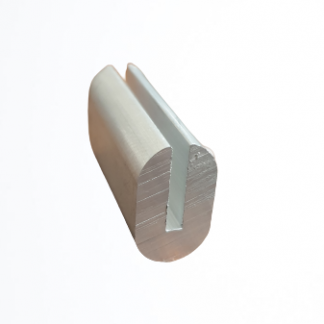

Aluminium Framing Channel – 2mm Gap

£3.00 – £21.44 ex VAT Select options This product has multiple variants. The options may be chosen on the product page

Showing all 6 results

Polycarbonate Sheeting

If you’re looking for a tough, shatterproof alternative to glass, then polycarbonate sheeting is a smart option. Not only is it highly durable, but it’s also an incredible 250 times stronger than glass. This combination of unique durability, as well as strong water and impact resistance, makes it an ideal choice for a range of applications. It also provides excellent heat resistance and is also flame-retardant and chemical resistant.

Polycarbonate sheet prices can also make it a more cost-effective option than glazing. It’s a highly versatile material and cutting polycarbonate sheeting is easier than working with glass.

How is it made?

Polycarbonate sheeting is made from a type of thermoplastic polymer known as polycarbonate resin. This resin is derived from bisphenol A (BPA) and phosgene and is processed into a polymer chain that has a high molecular weight and a crystalline structure. It’s this structure that gives polycarbonate sheeting its unique strength and durability.

This polymer chain is then formed into a sheet by a process known as extrusion. The material that this produces is highly versatile as well as strong and can be cut for a variety of applications and purposes.

Where is polycarbonate sheeting used?

Polycarbonate sheeting is widely used as a tough, shatter-resistant and durable alternative to glass. From polycarbonate greenhouse panels to clear roofing sheets, it’s widely used across different applications. In the construction industry, it’s frequently used as a glass substitute in skylights and roofing systems. Because polycarbonate sheeting combines High UV resistance with exceptional strength and shatter resistance, it’s often used in bus shelters, and other applications where weather exposure is a factor.

Polycarbonate sheeting is used widely across the industrial, manufacturing and engineering sector. It’s used for the creation of protective barriers and machine guards, as well as high-stress applications where resistance is required.

Because it’s transparent and lightweight, but also very strong, it’s also used for making protective covers and electronic housing. It’s also used widely in the vehicle industry, and for manufacturing medical and safety products. In fact, polycarbonate sheeting is an essential material in a range of high-demand applications.

What are the different thicknesses of polycarbonate sheeting and what are they used for?

Polycarbonate sheeting is available in a range of different thicknesses to suit different uses and applications. Factors such as the strength needed, weather conditions, and the potential impact resistance should all be taken into account. From 1mm polycarbonate sheeting to 25mm polycarbonate sheeting, and 35mm polycarbonate sheeting, there is a range of polycarbonate panels and sheeting available to suit your particular requirement.

- 2-4mm: This is a common thickness for small projects such as hobby or DIY applications, including greenhouse glazing and shed windows.

- 6-8mm: This thickness is suitable for more demanding applications, such as security windows and doors, as well as skylights and conservatories.

- 10-16mm: This thickness is suitable for more heavy-duty applications, such as industrial roofing and partitions.

- 20mm and above: This thickness is usually used for high-impact applications such as bullet-resistant glazing and riot shields.

Can polycarbonate sheeting be drilled?

Polycarbonate sheeting can be successfully drilled and at 1st Choice Metals, we provide a hole drilling service for 2mm and 3mm thick sheeting.

Polycarbonate sheeting from 1st Choice Metals

At 1st Choice Metals, we keep 2mm & 3mm thicknesses in stock with other thicknesses and colours available upon request. It’s easy to order and our experienced team is always on hand to answer any questions you may have

Place your order today or contact us to find out more.